- Language: English

- +91-9212012856

- +91 011-23219311-12, 011-66405958

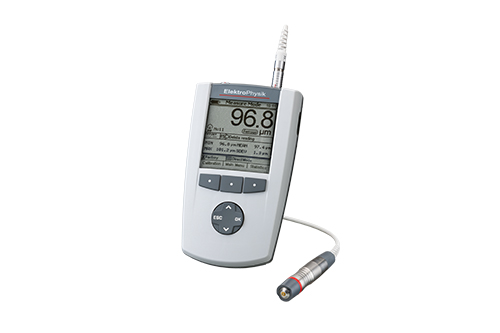

Coating Thickness Gauges MiniTest 7400

High-end Coating Thickness Gauges with a wide selection of external, interchangeable sensors.

The graphic display allows for direct display of statistical values, trend diagrams, histograms and simplified user guidance.

The MiniTest 7400 Coating Thickness Gauges device enables measurement of non-magnetic coatings (paint, synthetic material, chromium etc.) on a ferromagnetic substrate (steel) and of insulating coatings (varnish, enamel, synthetic material etc.) on conductive substrates (aluminium, copper, stainless steel).

The MiniTest 7400 makes it possible to take a wide range of measurements, from the thinnest coatings in the sub-micrometer range (e.g. galvanised coatings), difficult geometries of the objects to be measured (e.g. measurement of steel pins, measurement to be taken in recesses and holes, etc.) down to thick coatings (e.g. flame retardant coatings in steel constructions, rubber coatings etc.).

The SIDSP sensors are technologically advanced and unique in their accuracy and reproducibility on account of their manufacturing process. Despite high accuracy the sensors are wear resistant and withstand even years of use on rough surfaces. Each sensor is subject to a fully automatic factory test and provided with 50 calibration points for correction of even the slightest deviations. Furthermore, while manufacturing them each sensor is encoded with temperature compensation for automatic correction of the effect of temperature on the readings.

The MiniTest 7400 Coating Thickness Gauges device is operated via a graphic interface and provides help functions akin to those of a PC: context-specific help, filing of readings in folder structures and menu-driven navigation with symbols and text display. The user guidance is available in 4 languages, others are under preparation.

We would be happy to provide you with advice to select the right sensor; avail of our offer and call us or send us an email. Together we will determine what is the optimal configuration for you and even gladly assist you subsequently in operating the device. We owe it to our customers to provide consultation and it follows that it is offered free of cost.

Fields of Application

On account of the compact design and multi-functionality of the connectable sensors the device can be used for the most varied measuring jobs:

- Measurements to be taken on small parts, on thin metal bars or grooves call for our miniature sensors with the world's tiniest measuring tip of 2.5 mm / 0.1".

- We offer special sensors for auto body measurements with reduced sensitivity to factors relating to the geometry of the component and/or the thickness of the auto body sheet.

- In aircraft construction, there are different alloys used based on aluminum or titanium -

- our Coating Thickness Gauges automatically compensates for the different conductivities and can measure without recalibration on various non-ferrous substrates.

- There are special tube sensors to measure grooves, drill holes and spots not easily accessible.

- In the area of heavy corrosion protection, e.g. in large steel structures (bridges and shipbuilding), large amount of readings are taken on site and evaluated later. Here these instruments often known as paint thickness gauge.

- The robust heavy duty sensors are meant for use in environs prone to dust and moisture (construction sites, shipyards).

- When in need of measuring thicker coatings like fireproof coatings or special coatings in pipeline constructions, the F 15 sensors help measure up to 15 mm / 0.59" of Coating Thickness Gauges on steel.

- A special sensor is available for measurement on heavily abrasive surfaces with high surface roughness.

- In quality control labs the devices can be connected by USB or Bluetooth to your PC for further processing of measurement data, for e.g. with the CAQ software QUIPSY.

Application

Non-destructive Coating Thickness Gauges measurement of:

- Non-magnetic coatings like varnishes, enamels, chromium and zinc on ferromagnetic base materials (e.g. steel)

- Insulating coatings like varnishes and anodising aluminium and nonferrous metals (e.g. aluminium)

Characteristics

- Precision in Coating Thickness Gauges measurement of up to 100 mm / 4 inches

- Increased accuracy and reproducibility by sensor-integrated digital signal processing (SIDSP®)

- Universal probes with automatic substrate detection for quick measurements on steel and nonferrous metals

- Wear resistant probes with practically unlimited service life

- Optimal temperature compensation

- High precision characteristic curves with up to 50 data points in the factory calibration

- Storage for up to 100000 values

- User guidance in 4 languages, others under preparation

- Infrared data transmission (IrDA) to PC and printer

Scope of delivery

- MiniTest 7400 device

- Software MSoft 7 Professional

- User guidance German/English/French/Spanish

- Quick reference guide

- 4 AA cells, type LR06

- Plastic carrying case

| Property | Value | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Sensor embodiment |

|

|||||||||

| No. of measurement series |

|

|||||||||

| Measurement memory |

|

|||||||||

| Statistical functions |

Number of readings |

|||||||||

| Calibration |

Factory calibration |

|||||||||

| Additional calibration procedures according to international standards |

ISO 19840:2004(E) |

|||||||||

| Limit monitoring |

Optical and acoustical signaling |

|||||||||

| Measurement units |

|

|||||||||

| Data interface |

Bluetooth® 4.0 |

|||||||||

| Printer |

Standard ASCII printer |

|||||||||

| International standards |

DIN EN ISO 1461 |

|||||||||

| Display |

graphics display, adjustable lighting |

|||||||||

| Power supply |

2 batteries AA / LR-06 / Mignon |

|||||||||

| Operating temperature range |

-10 °C ... +60 °C / 14 °F ... 140 °F |

|||||||||

| Storage temperature range |

-20 °C ... +70 °C / -4 °F ... 158 °F |

|||||||||

| Dimensions |

157 mm x 75,5 mm x 49 mm |

|||||||||

| Weight |

|