- Language: English

- +91-9212012856

- +91 011-23219311-12, 011-66405958

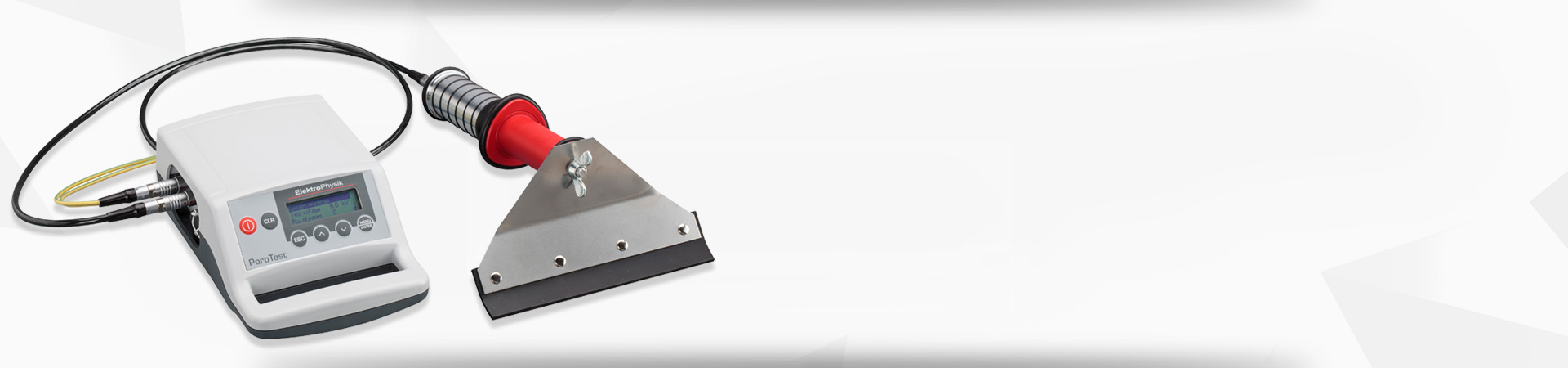

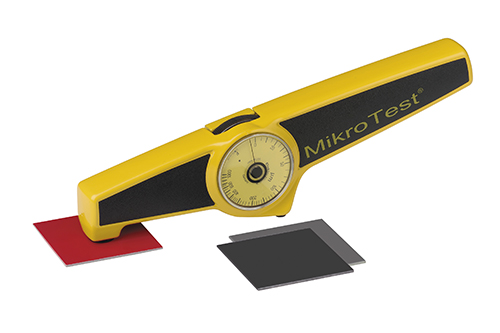

MikroTest

Magnetic Coating Thickness Gauges / DFT meter MikroTest

MikroTest is an extremely robust Coating Thickness Gauges, which measures the thickness of non-magnetic coatings on steel substrates on the magnetic attraction principle.

The special models of the MikroTest Ni series measure the thickness of electroplated nickel coatings on steel (MikroTest NiFe 50) and on non-ferromagnetic substrates (MikroTest Ni 50 und Ni 100).

The MikroTest is resistant to solvents and made extremely durable by the metal housing.

The magnets owe their long-lasting durability to the unique ElektroPhysik manufacturing process, which also makes them remain within the tolerance values for decades.

Application

Non-destructive measurement of:

- Non-magnetic coatings like varnishes, enamels, chromium and zinc on ferromagnetic base materials (e.g. steel)

- Electroplated nickel coatings on steel (only the NiFe 50 model)

- Electroplated nickel coatings on non-ferromagnetic substrates (e.g. aluminium, copper, synthetic materials etc.) (only the Ni 50 and Ni 100 models)

Features

- Heavy-duty zinc die-cast housing

- Magnet with long-lasting durability owing to the ElektroPhysik manufacturing process

- Measuring range up to 20 mm

- Can be used in all positions because of the weight compensation: horizontal, vertical, overhead

- Measurement also possible on curved surfaces

- Battery-free operation

Scope of delivery

- The MikroTest device

- Operating manual

- Soft case

MikroTest 5

Manually operated measuring mechanism. Turn the scale wheel to the forward stop and then slowly turn the wheel backwards by hand until the magnet releases from the object to be measured.

MikroTest 6

Automatic drive mechanism of the measuring device by tension spring storage. Before measuring the scale wheel is turned as far as it will go and once started the built-in locking mechanism automatically carries out the process of measurement.

| Property | Value | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Range |

| |||||||||||||||||

| Application | 6 S3; 6 S5; 6 S10 Enamel, plastic, rubber on steel*. 6 NiFe50 Electroplated nickel on steel*.

*Steel: ST 33 to ST 60 | |||||||||||||||||

| Tolerance |

| |||||||||||||||||

| Minimum surface |

| |||||||||||||||||

| Minimum curvature radius |

| | ||||||||||||||||

| Minimum base thickness |

| |||||||||||||||||

| Ambient temperature |

| |||||||||||||||||

| Dimensions and weight | Dimensions: Gauge 215 mm x 55 mm x 29 mm · Plastic carrying case 235 mm x 185 mm x 46 mm · Weight: Case incl. gauge approx. 560 g |